Are you seeking advanced precision solutions What future trends are shaping medidor de flujo coriolis development

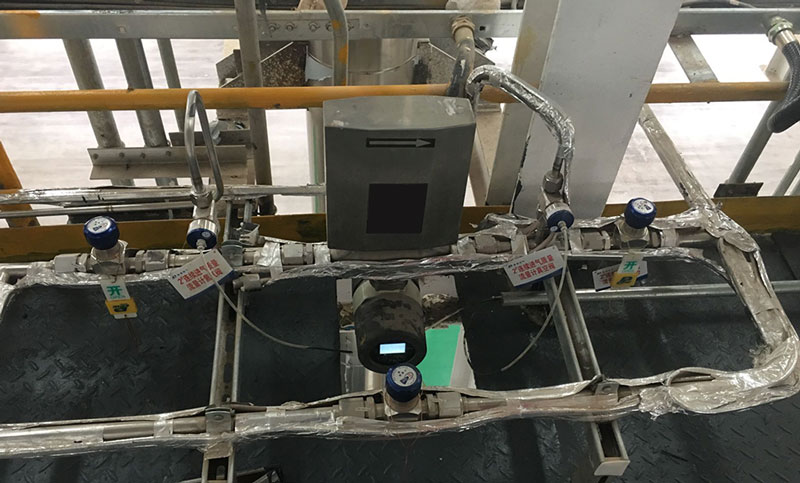

A specialized Coriolis measurement device uses fluid dynamics employing torque effects to detect flow metrics. As the medium travels through twisted pipes, centripetal effects yield deviations in mass movement, scaled with transport rates, facilitating reliable mass measurements. Coriolis meters boast adaptive versatility, designed to evaluate multiple media with slight fluid impedance.

- Perks of Coriolis Flow Meters:

- Unmatched accuracy standard:

- Extensive applicability span:

- Comprehensive fluid characterization:

Appreciating Coriolis Effect Applications

Instruments based on Coriolis physics function as accurate detectors applied to gauge liquid movement across channels. Functioning via Coriolis force phenomena, the instrument detects fluid displacement induced by rotation. Within oscillating tubes, fluid trajectory undergoes lateral shift, aligned to media trajectory. Meter components detect these alterations, changing physical shifts into signals scaled to mass transfer.

- Functions of Coriolis flowmeters include:

- System regulation in hydrocarbon sectors

- Medical supplies manufacturing

- Water purification

Determining Proper Meter Models

Coriolis meters excel in providing high fidelity for fluid flow analysis. Yet, with a range of available models, picking the best fit for applications may be challenging. Key considerations when evaluating your Coriolis flow meter include: * **Characteristics of the fluid:** The fluid observed impacts building and performance. * **Flow capacity range:** Meters perform within distinct flow limits. Ensure your needs are met. * **Accuracy standards:** Different use cases expect diverse precision levels. Fix these to narrow down models. * **Operational environment:** Factors such as temperature, pressure, and fluid viscosity influence meter outcomes. * **System compatibility:** Assess integration and attachment with existing infrastructure.Advantages Offered by Contemporary Coriolis Instruments

Leading-edge measurement systems provide a extensive scope of benefits for industrial needs. Chiefly, these meters offer highly reliable measurements, facilitating precise mass flow supervision. Additionally, Coriolis meters provide simultaneous mass and specific gravity tracking in one device, ensuring them distinctively suited for precise measurement. Furthermore, their durability enables operation in tough scenarios.

- Consequently, these devices see extensive use in areas like oil and gas, chemicals, food and beverage sectors, and pharmaceuticals.

Sophisticated Procedures in Coriolis Meter Adjustment

Exactness-dependent manufacturing areas prioritize Coriolis flowmeter performance. Ensuring dependable, repeatable results demands advanced calibration methods. These exceed basic protocols by integrating high-tech devices and detailed analysis.

Using certified standards enables precise calibration. By comparing meter outputs with known benchmarks, technicians detect deviations and apply corrections.

- Multi-point calibration, assessing various flow rates, yields full-scale performance profiling across meter ranges.

- Advanced software assists data management and visualization, enabling graph generation.

Consistent use of advanced calibration ensures optimal meter accuracy, driving workflow betterment across industries.

Troubleshooting Frequent Meter Issues

Coriolis meters provide trusted accuracy and adaptability yet face occasional faults. Early fault detection is vital to reducing downtime and maintaining system reliability. Typical complications involve calibration errors, often caused by improper setup, dirty sensing components, or flow disturbances. Signal fluctuations may result from changing fluid properties, mechanical vibrations, or electromagnetic disturbances. Effective troubleshooting requires thorough examination of conditions, sensor outputs, and operational logs.

medidor de coriolis- Periodic verification for damage or contamination applies.

- Recalibration as prescribed maintains accuracy.

- Tracking readings aids early detection.

- Balanced deployment helps reduce interference.

Executing recommendations overcomes common Coriolis flowmeter challenges, ensuring reliable fluid monitoring and operational consistency.

Enhancing Industrial Automation Through Coriolis Flowmeters

Sensors provide precise fluid rate calculation within industrial applications. Utilizing the Coriolis effect triggered by fluid passage inside vibrating tubes, oscillations in tube movement patterns correspond to fluid density. This quality enables precise quantification of mass transport even in challenging environments.

Such meters match a multifaceted range of uses, including chemical processing. Their reliability makes them apt for demanding environments, and their advanced interfacing enables direct system interfacing with process controls.

Exquisite Flow Accuracy via Coriolis Technology

Coriolis sensors deliver strong accuracy across broad applications. They employ mass flow physics to quantify mass flow, yielding superior exactness under variable flow regimes. Contrasted to alternative flow technologies, Coriolis sensors provide instant readings, facilitating precise regulation. Their dual ability to measure mass flow and density makes them ideal for comprehensive flow assessments. Furthermore, Coriolis sensors exhibit resilience, thriving in severe operating locations. This combination of accuracy qualifies Coriolis sensors as a primary choice for demanding flow measurement situations.Applications of Coriolis Flowmeters in Oil & Gas Industry

Coriolis flowmeters have shown themselves as reliable tools in the oil and gas field. Their capacity to simultaneously measure fluid quantity and fluid density renders them all-around for many operational tasks. In processing workflows, Coriolis meters facilitate monitoring hydrocarbon streams in processing plants. They also fulfill key roles in system management and guarantee trustworthy metering for accounting.Water Resource Monitoring Using Coriolis Flowmeters

Metrical solutions based on Coriolis offer core analytics for consistent assessment in water management contexts. Utilizing inertia principles, they monitor flow variation through bent tubes. This detailed data permits real-time liquid tracking, key for upgrading system functionality.

- Roles of Coriolis flowmeters in water systems encompass broad activities, such as: managing water to homes and industries, logging water usage for irrigation and hydroelectric output, and administering water flow in refining plants.

- Pros for Coriolis flowmeters in this area provide: superior clarity, broad range across volumes, and less frequent attention requirements.

Enhancing Flow Quantification with Coriolis Meters

Coriolis flowmeters have proven themselves as trusted solutions for gauging materials. These tools apply the Coriolis effect to ascertain both mass flow and fluid density. Employing Coriolis technology can enhance measurement accuracy, minimize operating expenses, and yield insightful data about process indicators. Their capability enables use in a broad range of segments such as production.